Relationship between the burnishing process used by Mizuno and the Storms theory of NAE formation

Copyright by Edmund Storms August 2019. May be quoted freely with attribution.

Relationship between the burnishing process used by Mizuno

and the Storms theory of NAE formation [.pdf] by Edmund Storms Kiva Labs, Santa Fe, NM (8/1/19)

INTRODUCTION

Mizuno [1] has applied Pd to Ni mesh by burnishing and claimed to make excess energy by heating the material in D2 gas. This method is expected to produce the conditions predicted by Storms to cause LENR. The relationship between the burnishing method and the Storms theory of LENR is described as well as several testable predictions.

DISCUSSION

The LENR process involves two separate and independent events, one involving a common chemical process and the other caused by a unique nuclear process. The first event creates a condition in the material in which the nuclear process can function. Without this condition being present, the nuclear process cannot take place. But once this special condition forms, the nuclear process occurs without further delay. The difficulty in causing the LENR process results from failure to create this required special condition.

According to the Storms’ theory[2], this special condition, called the NAE (Nuclear Active Environment), consists of physical gaps having dimensions of a few nanometers between the atomic planes. Such gaps can be formed in many different ways, but up to the present time they have resulted when stress is relieved at random sites within the physical structure. The stress is created when the material, usually palladium, reacts with isotopes of hydrogen, thereby causing expansion. Removal of the hydrogen causes contraction, during which time most of the gaps (cracks) form. This counter intuitive conclusion results because the expansion resulting during reaction with hydrogen produces mainly compressive stress, which on average would not produce gaps. Removal of hydrogen produces contraction that results in the kind of stress required to produce gaps. Consequently, according to the Storms model, the Pd must experience deloading at one time during the study for LENR to be triggered.[3] Once formed, the NAE seems to be stable for long periods of time.

After a gap forms, generally at a grain boundary, the local stress can be relieved most easily by making the gap wider rather than by causing other gaps to form. This natural tendency causes the initial small gaps to grow wider and form what can be clearly seen as cracks rather than remain small enough to cause LENR. This process results because less energy is required to move atoms further apart once the atomic bond as been broken than is required to break the bond in the first place. Nature will always take the path of least resistance. This conventional process explains why LENR is not initiated even though many cracks are clearly observed.

The amount of overall dimensional change, hence amount of stress, is related to the amount of hydrogen that reacts, thereby causing an apparent relationship between the maximum D/Pd ratio achieved by the material and the amount of excess energy resulting from formation of numerous gaps.[4] Although, palladium is normally used to form the required gaps, which is the example used in this paper, other materials can be expected to experience the same process and consequently produce LENR.

The greater the number of gaps having the required dimension, the greater the overall rate of LENR. Because suitable gaps are rarely produced in conventional materials, the challenge is to modify the material such that a large number of independent small gaps can form during loss of hydrogen or by other means. The application of Pd to a Ni surface by the burnishing process, as used by Mizuno, achieves this requirement in two ways.

The first requirement is achieved because Pd is applied an amorphous form. Upon reaction with hydrogen, this non-crystalline structure would convert to the fcc structure at many independent sites. We can expect the resulting stress to cause many isolated gaps to form within the Pd layer. Additional gaps (cracks) would form at the Pd-Ni interface as result of the Pd expanding more than the Ni because the Pd reacts to a much greater extent than does Ni. Of great importance is that each of these processes takes place at many independent sites, with the stress not focused on only a few sites as is normally the case.

The second requirement involves the small particles of NiO that would be removed from the Ni surface and mixed with the Pd layer. A gap would be expected to form between the surrounding Pd metal and this inert inclusion, as hydrogen is lost from the structure.

If this description were correct, it would be expected to apply to all Pd found to produce LENR. I predict that commercial Pd observed to support LENR contains similar unintended inclusions that remain in the metal after the refining process and were not altered when the metal was formed into wire or sheet. Consequently, most pieces of the batch are found to produce LENR regardless of the final form created by physical means. This behavior explains why some batches of commercial Pd produce LENR for no obvious reason.

As an example, Fleischmann has described how boron is added to the molten Pd during the purification process to remove oxygen by formation of insoluble boron oxide, which floats to the surface and is physically removed. In view of the Storms model, the small pieces of oxide scattered throughout would make the Pd eventually nuclear active rather than the absence of oxygen.

EXPERIMENTAL

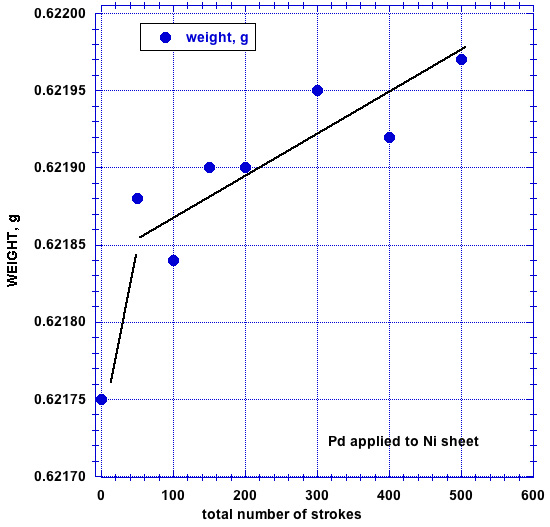

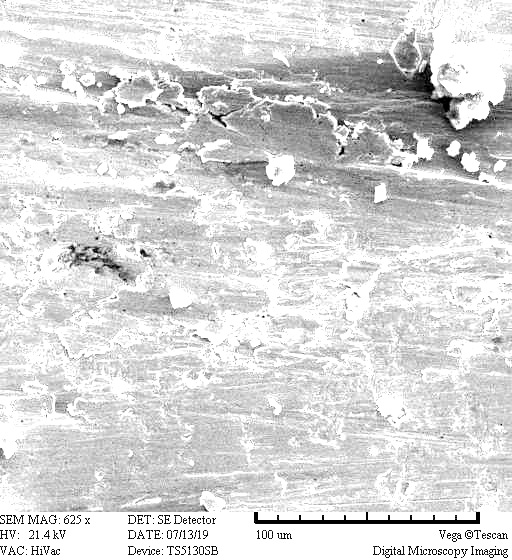

The burnishing process was explored by rubbing a Pd rod against a 1 mm thick piece of Ni (1 cm x 2 cm) that had been previously electroplated with Pd. No NiO would be expected to be present on the Ni surface. As shown in Fig. 1, the amount of Pd transferred from the rod to the Ni was a linear function of the number of strokes after the first 50 strokes. In other words, each stroke transferred the same amount of Pd. The surface acquired a smooth bright metallic appearance where the rubbing had been applied. Fig. 2 shows islands of Pd, some of which appear to be poorly attached. This sample will be studied to determine what happens during reaction with D in the absence of included NiO.

FIGURE 1. Weight gain of the Ni sheet as result of pressing the edge of a Pd rod against the surface and moving it across the full length of the Ni plate. Each stroke was made at a random location on the surface so that most of the surface was eventually burnished with Pd.

FIGURE 2. SEM picture of a surface to which Pd was applied using the burnishing method. The Ni had been previously electroplated with Pd. Notice the islands of Pd. By eye, the surface looked polished and reflective where the burnishing had been applied.

A second sample of Ni was flame heated to about 800° C to form a visible (blue color) oxide layer after which it was burnished in the same way as the first sample. Although the blue color was removed to produce a bright metallic surface, no detectable weight increase (±0.00005 g) was produced after 600 strokes. Apparently the nature of the Ni surface affects the amount of Pd transferred to the surface. Consequently, the condition of the surface is revealed as being another important variable. This condition needs to be explored.

Any material that is not firmly attached to the surface would be expected to be pushed aside by the burnishing process and not be included in the Pd layer.

These samples will be first studied using electrolytic loading to determine how the Pd layer affects the uptake of D into the Ni using methods previously described.[5] The production of excess energy will be studied up to 85° C in D2O. If energy is detected, the samples will be studied in D2 gas up to 350°C.

CONCLUSIONS

Replicating exactly the procedure used by Mizuno is not as important as replicating what Mizuno caused. If he actually caused LENR, this result could be produced many different ways, as is typical of all natural phenomenon including LENR. Identifying the important variables becomes important so that the resulting LENR process can be replicated at will with total control. Some of these variables are suggested below as predictions. If these suggested methods cause LENR, this would provide further evidence that the NAE suggested by Storms is correct.

Although Storms also proposed a mechanism for the nuclear process, this part of the theory is not important when trying to create the conditions initiating the nuclear process because once the NAE forms, the nuclear process starts without any further knowledge or effort being required. Consequently, learning how to make and control the production of the NAE is the only important knowledge needed to cause and use LENR. Absence of this knowledge has been the reason for general rejection and why the various efforts have failed to make useful energy.

PREDICTIONS

- Use of Ni that has been slightly oxidized by being heated in air to a temperature sufficient to cause thickening of the oxide layer will be more nuclear active than clean Ni.

- Use of Ni sbeet rather than a mesh will increase the effectiveness of the process by increasing the surface area of the deposited Pd.

- Use of other metals that form an oxide surface layer, such as Ag, Cu, Ti, and Fe, will be suitable as a substrate to which Pd is applied.

- Application of surface layers other than oxide to the substrate can be expected to improve the effectiveness of the process.

- Other metals that form hydrides, such as Rh, Ti, Zr, or Hf, should cause LENR when used as the burnished material.

- Use of softer alloys of Pd, such as Pd-Li, are expected to produce a more effective burnished layer compared to pure Pd. This alloy might also be more effective because it is more reactive to hydrogen than pure Pd.

- Burnished Pd can be expected to produce LENR when used as the cathode during electrolysis and gas discharge, as well as when the gas loading method of Mizuno is used.

References

(1) Mizuno, T. and J. Rothwell Increased Excess Heat from Palladium Deposited on Nickel (Preprint) in The 22nd International Conference for Condensed Matter Nuclear Science ICCF-22. 2019. Assisi, Italy. http://lenr-canr.org/acrobat/MizunoTincreasede.pdf, https://www.lenrcanr.org/acrobat/MizunoTsupplement.pdf

(2) Storms, E. How Basic Behavior of LENR can Guide A Search for an Explanation. JCMNS 2016, 20, 100.

Storms, E. K. A Theory of LENR Based on Crack Formation. Infinite Energy 2013, 19 (112), 24.

Storms, E. K. An Explanation of Low-energy Nuclear Reactions (Cold Fusion). J.Cond. Matter Nucl. Sci. 2012, 9, 85.

(3) Storms, E. Anomalous Energy Produced by PdD. JCMNS 2016, 20, 81.

(4) McKubre, M. C. H.; Crouch-Baker, S.; Riley, A. M.; Smedley, S. I.; Tanzella, F. L. Third International Conference on Cold Fusion, “Frontiers of Cold Fusion”, Held at: Nagoya Japan, 1992; p 5.

Castagna, E.; Sansovini, M.; Lecci, S.; Rufoloni, A.; Sarto, F.; Violante, V.; Knies, D.; Grabowski, K. S.; Hubler, G. K.; McKubre, M. C.et al. 14th International Conference on Condensed Matter Nuclear Science, Washington, DC, 2008; p 444.

(5) Storms, E. In ICCF-21 Fort Collins, CO, 2018.

Relationship between the burnishing process used by Mizuno

and the Storms theory of NAE formation [.pdf] by Edmund Storms Kiva Labs, Santa Fe, NM (8/1/19)